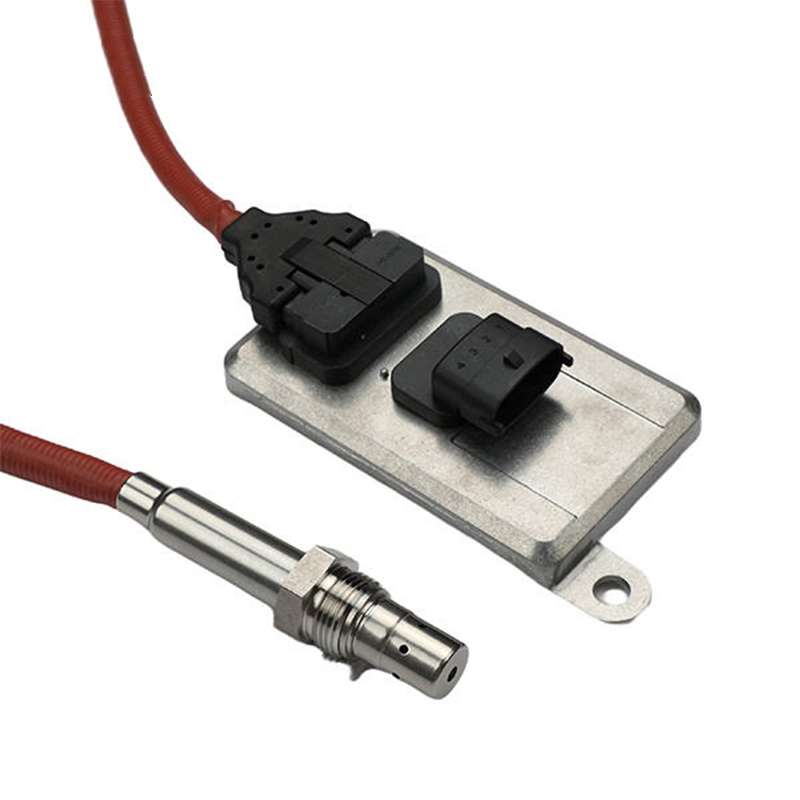

Introduction to Nox Sensor 5WK96628C 2011649

YZHIDIANF’s nox sensor 5WK96628C 2011649 is designed to meet the needs of efficient emission control for DAF CF65/CF75/CF85 series (2001-2013 models) commercial vehicles. As a core component of the engine aftertreatment system, the sensor ensures that the vehicle meets the Euro IV to Euro VI emission standards by monitoring the concentration of nitrogen oxides (NOx) in the exhaust gas in real time, while optimizing fuel efficiency and engine performance. With precision ceramic sensor elements and high-temperature resistant alloy housing, the nox sensor 5WK96628C 2011649 can still maintain stable output under harsh working conditions and is suitable for a variety of diesel engine platforms.

Function of Nox Sensor 5WK96628C 2011649

Accurate Monitoring and Data Transmission

- Built-in high-sensitivity electrochemical unit, which can detect the NOx concentration in the exhaust gas in real time, with an error rate of less than ±2%, ensuring that the ECU accurately adjusts the urea injection amount.

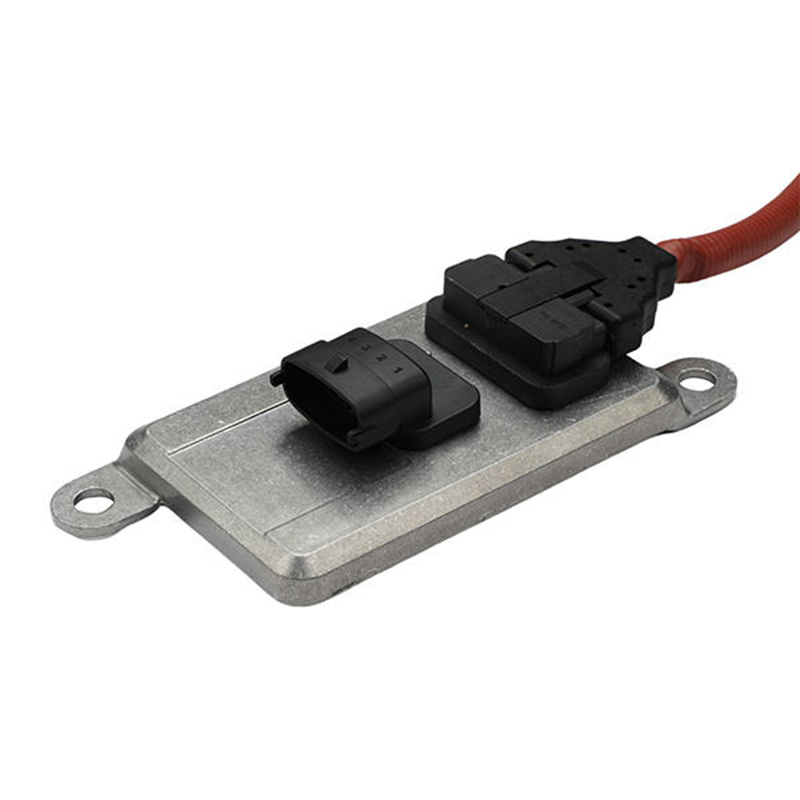

- Supports CAN bus communication protocol, seamlessly connects with the vehicle ECU, provides fast response (<0.5 seconds) and continuous data flow, and avoids the risk of excessive emissions.

Environmental Adaptability

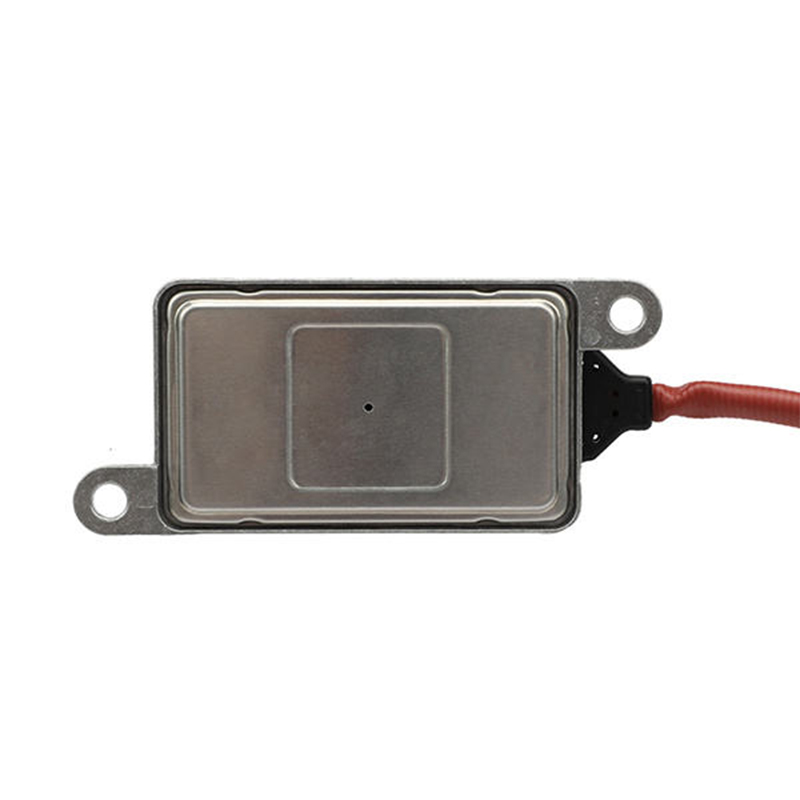

- With IP67 protection level design, it can withstand extreme temperatures and high humidity environments from -40℃ to +900℃, and is suitable for a variety of scenarios such as long-distance transportation and mining operations.

- The anti-vibration design has passed the ISO 16750-3 standard test to ensure signal stability under bumpy road conditions.

Compatibility and Diagnostic Support

- Supports direct replacement with the original 5WK96628C sensor without modifying the wiring harness or software adaptation.

- Built-in self-diagnosis function can trigger fault codes (such as P2200, P2201) to facilitate rapid troubleshooting of system abnormalities.

Advantages of Nox Sensor 5WK96628C 2011649

Excellent Durability

- The core sensor element adopts platinum coating technology, with a lifespan of 150,000 kilometers or 5 years (whichever comes first), far exceeding the industry average of 100,000 kilometers.

- After 1,000 hours of salt spray test and 2,000 thermal shock cycle tests, the corrosion resistance is improved by 40%.

High Efficiency and Energy Saving

- The optimized signal processing algorithm can reduce urea consumption by about 8%, saving more than $300 in annual SCR system operation and maintenance costs.

- Low power consumption design (working current ≤50mA) reduces the load on the vehicle’s electrical system.

Applications of Nox Sensor 5WK96628C 2011649

- Applicable models: DAF CF65/CF75/CF85 series (2001-2013 models), compatible with PACCAR MX series engines (MX-11, MX-13).

- Adaptation system: SCR (selective catalytic reduction) system, EGR (exhaust gas recirculation) system and DPF (diesel particulate filter) integrated post-processing platform.

- Industry application: long-distance logistics fleet, municipal sanitation vehicles, construction machinery and heavy transportation equipment.

FAQ

Q1: Is this nox sensor 5WK96628C 2011649 compatible with non-DAF brand vehicles?

A: 5WK96628C 2011649 is designed for DAF CF series, but it can be adapted to some MAN and Volvo models with the same type of sensor after testing. It is recommended to provide the VIN code to confirm compatibility.

Q2: Does the ECU need to be reprogrammed after installation?

A: No programming is required, plug and play. If the vehicle reports a fault code, it is recommended to use a diagnostic tool to reset the SCR system adaptation value.

Q3: How to determine whether the nox sensor 5WK96628C 2011649 needs to be replaced?

A: Typical signs include: the engine fault light is always on, abnormal increase in urea consumption, excessive exhaust emissions or reduced power. It is recommended to perform NOx concentration calibration every 60,000 kilometers.

Q4: Can the nox sensor 5WK96628C 2011649 be directly removed in a high temperature environment?

A: It is strictly forbidden to operate when the engine is running or not cooled! Wait until the exhaust temperature drops below 50℃ and use a special anti-seizing agent to remove it to avoid thread damage.