I. The behind-the-scenes hero of the automobile industry

In modern society, cars have long been an important tool for people to travel, shuttling through the streets of cities. However, it is inseparable from the joint efforts of countless auto parts suppliers and manufacturers to change a car from design drawings to finished products. They are like the core ties of the industrial supply chain, closely linked, supporting the vigorous development of the entire automobile industry. Next, let’s explore their key roles in the automobile industry.

II. Auto parts suppliers: diversified supply and stable guarantee

2.1 Wide coverage of the supply system

There are many kinds of suppliers of auto parts, and the products they supply cover all systems of automobiles.

2.1.1 Key role of fuel system

Take fuel system parts as an example, fuel nozzles and oil pumps are the key components. The fuel injector is just like the precise “fuel injection commander” of the engine. It can inject the fuel into the cylinder in a uniform and fine mist through extremely precise design. This process is by no means a simple matter. The timing and quantity of fuel injection need to be perfectly matched with the operating conditions of the engine. For example, when the engine is running at high load, the fuel injection nozzle should increase the fuel injection quantity quickly to ensure sufficient fuel supply to meet the demand of strong power output; In idle or low load state, the fuel injection quantity should be accurately controlled to avoid fuel waste and reduce fuel consumption. The oil pump is like the “power heart” of fuel transportation, which steadily pumps the fuel out of the fuel tank and delivers it to the engine at a certain pressure. The stability of its work is directly related to whether the engine can continue to operate normally. Once the oil pump fails and the fuel supply is interrupted, the engine will stop working immediately.

2.1.2 “Single spark” of ignition system

The spark plug in ignition system parts, though small, has the magical power of “igniting power”. The spark plug produces an electric spark at the right moment, which is like a spark, instantly igniting the combustible mixed gas in the cylinder, causing intense combustion and expansion, pushing the piston to move, and then driving the engine to run. The performance of spark plug directly affects the starting performance, power output and fuel economy of the engine. High-performance spark plug can produce stronger and more stable electric spark, which makes the mixed gas burn more fully, and the power performance of the engine is naturally better, while reducing fuel consumption.

In the daily use of cars, we can also really feel the importance of these parts. When the vehicle is difficult to start, it is likely that there is a problem with the spark plug and it cannot produce enough electric spark; However, if the vehicle has insufficient power and increased fuel consumption during driving, the working conditions of the fuel injector and oil pump need to be checked emphatically.

2.2 The significance of supply stability

Stable supply is the key to the smooth progress of automobile production. For automobile manufacturers, once there is a problem in the supply of parts, the production rhythm will be disrupted.

2.2.1 Chain reaction of brake system parts shortage

Taking braking system parts as an example, the shortage of brake pads, brake discs and other parts will directly lead to the failure of normal assembly of automobile braking systems. This will not only delay the production progress of the car, but also affect the delivery time of the car, which will bring huge economic losses and reputation damage to the car manufacturers.

In the automobile production line, every link is closely connected, just like a clock running precisely. If the brake system parts are not supplied, the whole production line will be pressed as if the pause button, and other processes can only wait. During this period, production equipment is idle and workers stop working, which will generate a lot of extra costs every day. Moreover, cars cannot be delivered to consumers on time, which will make consumers dissatisfied with car brands and affect the brand’s reputation and market image. In the long run, this may lead to the loss of consumers and the decline of market share.

2.2.2 Supplier’s strategy of ensuring supply

In order to ensure a stable supply, auto parts suppliers often need to establish a huge inventory system in case of emergency. At the same time, they will also establish close cooperation with many raw material suppliers to ensure the stable supply of raw materials. Some powerful suppliers will even lay out production bases around the world to spread supply risks. For example, a well-known auto parts supplier has factories in Asia, Europe and America. When there is a supply problem in one region, factories in other regions can quickly adjust their production plans to ensure the needs of global automakers.

III. Auto parts manufacturers: technology leading, quality first

3.1 Technological innovation drives development

Auto parts manufacturers are always at the forefront of technological innovation.

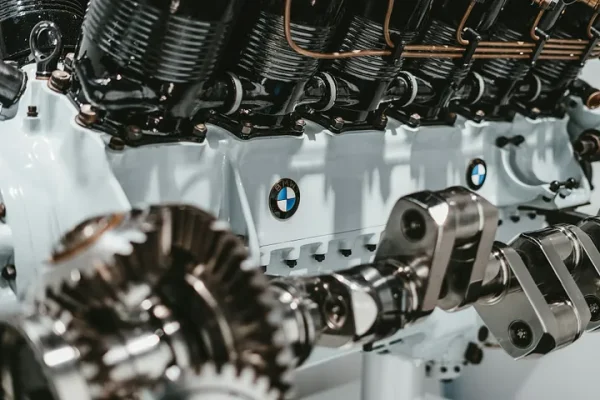

3.1.1 Technical Breakthrough of Engine System

In the manufacturing field of engine system parts, in order to improve the efficiency and performance of engines, manufacturers are constantly exploring new technologies and materials. For example, using lightweight aluminum alloy material to make engine cylinder block can not only reduce the weight of engine, but also improve fuel economy. Aluminum alloy material has the characteristics of low density and high strength. Compared with traditional cast iron material, using aluminum alloy to make cylinder block can greatly reduce the weight of engine and the energy consumption of the whole vehicle. At the same time, the heat dissipation performance of the engine has also been improved, because aluminum alloy has better thermal conductivity, which can dissipate the heat generated by the engine more quickly and ensure the stable operation of the engine under various working conditions.

In turbocharging technology, auto parts manufacturers are also constantly innovating. The traditional turbocharging technology has a certain phenomenon of turbine lag, that is, it takes a short time for the turbine to get involved in the work after stepping on the accelerator, which leads to the untimely power output. Now, some advanced turbocharging technologies effectively reduce the turbo lag by means of electronic turbocharging and variable cross-section turbocharging, so that the engine can still output powerful power under the condition of small displacement. This not only satisfies consumers’ pursuit of power, but also conforms to the current environmental protection trend of energy saving and emission reduction.

In the actual driving experience, cars equipped with advanced turbocharged engines are more rapid in acceleration and more sensitive in dynamic response. No matter the frequent start and stop on urban roads or overtaking on highways, it can be easily handled, bringing drivers a more enjoyable driving experience.

3.1.2 Intelligent upgrade of steering and control system

In steering and control system parts, the emergence of electronic power steering technology makes driving easier and more accurate. By developing advanced sensors and control systems, auto parts manufacturers have realized intelligent adjustment of steering force and improved driving experience and safety. For example, when driving at a low speed, the system will automatically reduce the steering assistance, so that the driver can control the vehicle more easily; When driving at high speed, the steering assistance will be weakened appropriately to increase the stability of the vehicle and avoid danger caused by excessive steering.

3.2 Strictly control the quality level

Quality is the lifeline of auto parts manufacturers.

3.2.1 Adhere to the quality of components of the emission system.

When producing emission system parts, manufacturers strictly follow environmental protection standards and strictly control the production process and quality of three-way catalytic converters and other parts. Three-way catalytic converter is the key equipment for automobile exhaust purification. It contains many precious metal catalysts, which can convert harmful gases such as carbon monoxide, hydrocarbons and nitrogen oxides in automobile exhaust into harmless carbon dioxide, water and nitrogen.

In order to ensure the performance of three-way catalytic converter, manufacturers need to strictly monitor every link in the production process. From the procurement of raw materials, only precious metals that meet the requirements of high purity are selected; In the production process, advanced coating technology is adopted to ensure that the catalyst is uniformly attached to the carrier and improve the catalytic efficiency; In the finished product inspection stage, the purification effect of the three-way catalytic converter is comprehensively inspected by using high-precision inspection equipment. Only products that have passed strict inspection will be allowed to enter the market.

If the quality of the three-way catalytic converter is not up to standard, the harmful substances in automobile exhaust can not be effectively purified, which will cause serious pollution to the environment. Moreover, cars that do not meet the emission standards will also face problems such as failing the annual inspection and being limited on the road, which will bring a lot of inconvenience to the owners. Therefore, the strict quality control of auto parts manufacturers is not only responsible for consumers, but also for the whole social environment.

3.2.2 Multi-link guarantee of parts quality

In addition to emission system components, manufacturers also pay attention to quality control in the production of other components. Before production, raw materials are strictly inspected to ensure that they meet quality standards; In the production process, advanced production equipment and technology are adopted to monitor each working procedure in real time; After the production is completed, conduct comprehensive quality inspection, including appearance inspection and performance test. Only the parts that pass the layer-by-layer inspection can enter the next link and finally be assembled into high-quality cars.

IV. Hand in hand: close cooperation in the supply chain

4.1 Collaborative R&D: Accelerate the pace of innovation

It is very important for auto parts suppliers and manufacturers to cooperate in product research and development.

4.1.1 Collaborative optimization of air intake system

Taking air intake system parts as an example, in order to improve the intake efficiency of engines, auto parts suppliers and manufacturers jointly carry out research and development work. By virtue of their expertise in materials and parts manufacturing, suppliers provide high-performance air filters and air intake duct designs. For example, the new air filter uses special filter materials, which can not only filter impurities in the air more effectively, but also reduce the intake resistance and let more air enter the engine. By optimizing the design of the intake pipe, the turbulence of air during transportation is reduced, and the uniformity and speed of air intake are improved.

Auto parts manufacturers optimize and integrate the air intake system according to the overall performance requirements and design concepts of the automobile. They will consider the power output requirements of the car, the layout of the engine compartment and the aerodynamic characteristics of the whole car. Through the close cooperation between the two parties, the intake system can better meet the working requirements of the engine and improve the dynamic performance of the car. A car with an optimized intake system will be more powerful when accelerating and the engine will respond faster.

4.1.2 Joint innovation of safety and auxiliary systems

This synergistic effect is more obvious in the research and development of safety and assistance system parts. Automobile manufacturers put forward functional requirements for intelligent driving assistance systems, such as automatic emergency braking, adaptive cruise, lane keeping assistance and so on. Component suppliers are responsible for developing and producing related sensors, controllers and other components. For example, as a key sensor in the intelligent driving assistance system, lidar can obtain the environmental information around the vehicle in real time and provide data support for automatic emergency braking and other functions. Suppliers and manufacturers jointly test and verify, constantly optimize system performance, and promote the rapid development of automobile safety and auxiliary technology. Nowadays, more and more cars are equipped with advanced intelligent driving assistance systems, which greatly improve the safety and convenience of driving.

4.2 Information sharing: improving supply chain efficiency

In the whole supply chain of automobile industry, information sharing is the key to improve efficiency.

4.2.1 Real-time communication between production plan and inventory

By establishing an efficient information communication platform, auto parts suppliers and manufacturers can realize real-time sharing of production plans, inventory status and other information. When the automobile manufacturer adjusts the production plan, it can timely transmit the information to the supplier, so that the supplier can make production preparation and inventory adjustment in advance. For example, if an automobile manufacturer plans to increase the output of a certain model, the supplier can arrange the purchase of raw materials in advance and adjust the production shifts according to this information to ensure the timely supply of parts.

Similarly, auto parts suppliers and manufacturers can also feed back the production progress and delivery information of parts to the manufacturer, which is convenient for the manufacturer to arrange the production and assembly process reasonably. If the production of a part is delayed, the supplier will inform the manufacturer in time, and the manufacturer can adjust the production sequence, give priority to assembling other models, or take temporary inventory deployment measures to avoid the shutdown of the production line.

4.2.2 Improvement of benefits brought by information sharing

This smooth flow of information effectively avoids inventory backlog and production delay, and improves the overall operation efficiency of the supply chain. Through information sharing, the supply chain of the automobile industry is like an organic whole, and all links closely cooperate and work together, greatly improving the competitiveness of the whole industry. At the same time, information sharing can also help enterprises reduce costs, improve resource utilization and achieve sustainable development.

V. Summary: the strength of the bond drives forward

As the core link of the supply chain of the automobile industry, auto parts suppliers and manufacturers jointly promote the continuous development of the automobile industry in the supply, manufacturing, research and development and cooperation of various system parts. From fuel system to safety auxiliary system, from technological innovation to cost control, every link embodies the wisdom and efforts of both sides.